Manufacturing and tooling technologies for the mobility of the future

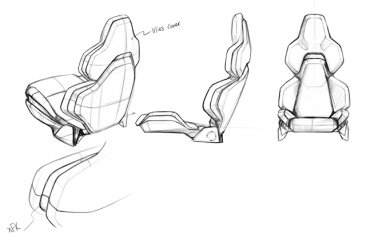

The ultralight construction of the seat is based on the consistent use of the latest technologies. The award-winning lightweight seat is around 20 percent lighter than competing products. In order to realize the lightweight design concept, Alba developed innovative manufacturing and tooling technologies for ultralight PU moulded foam parts and fiber tile. In addition, a new tool concept for hybrid carbon fiber composite lightweight construction on single strands and for lightweight sandwich cladding parts from Alba specifically designed for the ultra-lightweight seat has been designed. The concept is rounded off by the use of metal and PUR 3D printing as well as sustainable and highly heat-conductive seat cover fabric. In addition to the lightweight construction record, the prototype shows what is feasible in the seating area beyond the established modular systems. The seating concept is conceivable for hypercars, sports cars or future air taxis.

Ultra-lightweight seat already awarded several times

In addition to the current award with the German Design Award, the ultra-lightweight seat has already won the German Innovation Award in the categories “Automotive Technologies” and “Design Thinking” as well as the Altair Enlighten Award in the category “Future of Lightweighting”.